In the realm of industrial automation and control systems, pneumatic valves play a crucial role in regulating the flow of compressed air and other gases. These valves serve as essential components that help control and direct the movement of fluids, enabling precise and efficient operation in a wide range of applications. In this blog post, we will delve into the world of pneumatic valves, exploring their functionality, types, and applications.

The Basics of Pneumatic Valves

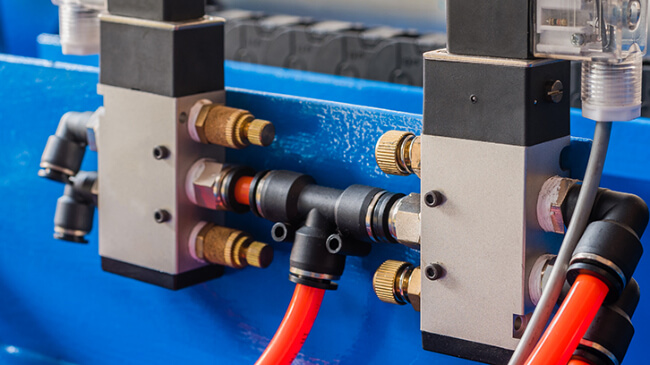

Pneumatic valves are devices designed to control the flow of compressed air or gases in a pneumatic system. These valves are responsible for starting, stopping, and directing the flow of fluid within a circuit. By manipulating the valve, operators can regulate the fluid’s pressure, flow rate, direction, and actuation in a controlled and predictable manner.

Understanding Valve Functionality

- Valve Actuation: Pneumatic valves are actuated either manually or electronically. Manual valves require physical manipulation, such as a lever or button, to control the flow. On the other hand, electronically actuated valves can be controlled remotely through an electrical signal, enhancing precision and automation.

- Valve Operation: Pneumatic valves commonly operate using one of two principles: on/off control or proportional control. On/off control valves provide binary functionality, enabling the fluid flow to be either fully open or fully closed. Proportional control valves, however, allow for more precise adjustment of flow rates, making them suitable for applications that require varying degrees of fluid control.

Types of Pneumatic Valves

- Directional Control Valves: These valves manage the direction of fluid flow in a pneumatic system. They typically feature multiple ports and are classified into different configurations:

- 2/2-Way Valves: These valves have two ports, one inlet, and one outlet, allowing or blocking the flow of fluid.

- 3/2-Way Valves: With three ports, these valves provide two flow paths, allowing operators to alternate between the two.

- 4/2-Way Valves: These valves have four ports and two positions, enabling fluid flow in one direction while blocking it in the other.

- 5/2-Way Valves: Equipped with five ports and two positions, these valves provide two distinct flow paths.

- Pressure Control Valves: These valves regulate the pressure of the fluid within a pneumatic system, ensuring it remains within the desired range. Pressure control valves can be further categorized into:

- Pressure Relief Valves: These valves open when the pressure exceeds a specific threshold, allowing fluid to escape and maintaining the desired pressure level.

- Pressure Reducing Valves: These valves reduce the incoming pressure to a predetermined lower pressure.

- Pressure Sequence Valves: Used in systems with multiple actuators, these valves enable sequential operation by controlling the pressure applied to each actuator.

- Flow Control Valves: Flow control valves manage the rate of fluid flow in a pneumatic system. They are commonly used to control the speed of actuators, ensuring smooth and precise movement. Two types of flow control valves are:

- Restrictive Valves: These valves feature an adjustable orifice or valve that limits the flow rate of the fluid.

- Non-Return Valves: Also known as check valves, they allow fluid flow in one direction while preventing backflow.

Applications of Pneumatic Valves

Pneumatic valves find extensive use in various industries, including manufacturing, automotive, oil and gas, pharmaceuticals, and many others. Some common applications include:

- Automated Manufacturing Systems: Pneumatic valves play a vital role in controlling the movement and operation of robotic arms, conveyors, and assembly lines.

- HVAC Systems: Pneumatic valves regulate the flow of air and fluids in heating, ventilation, and air conditioning systems.

- Process Control: Pneumatic valves enable precise control over the flow and pressure of fluids in industrial processes, such as in chemical plants or water treatment facilities.

- Transportation: Pneumatic valves are employed in braking systems, suspension systems, and air-powered actuators in vehicles.

Pneumatic valves are fundamental components in pneumatic systems, providing control over fluid flow, pressure, and actuation. By understanding the different types of pneumatic valves and their applications, engineers and operators can make informed choices to optimize their systems’ performance and efficiency. Whether it’s directional control, pressure regulation, or flow control, pneumatic valves continue to be indispensable tools in the world of industrial automation, driving progress in a wide range of industries.