MACHINE CONDITION

– The machine is in the stopped state,

– Connected to JOG workspace,

– cold molds,

MATERIAL NEED

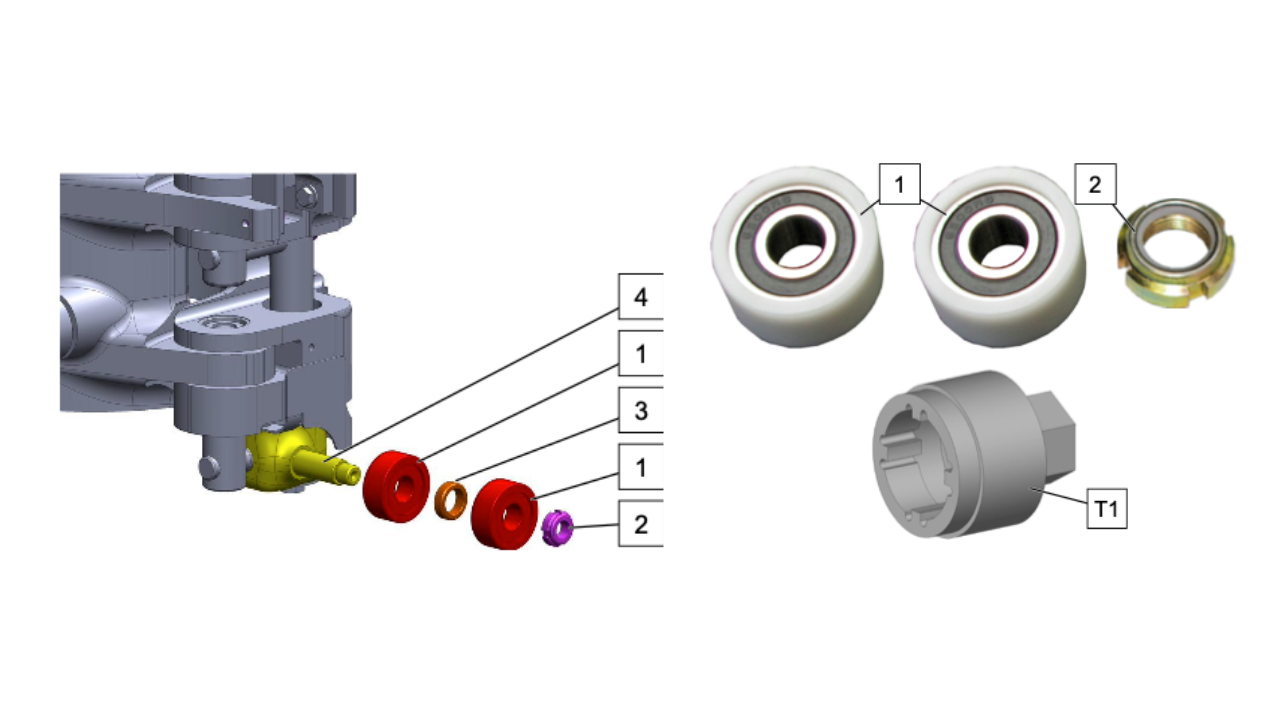

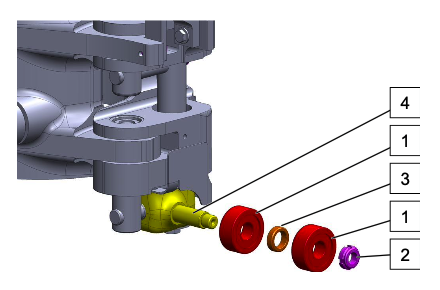

Piece

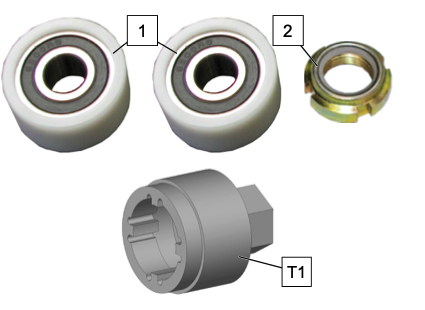

– Locking cylinders (1),

– Notched locknut (2).

consumable

– Clean and dry cloths.

special tool

– Tool (T1) (code 01159173801).

PROCEDURE

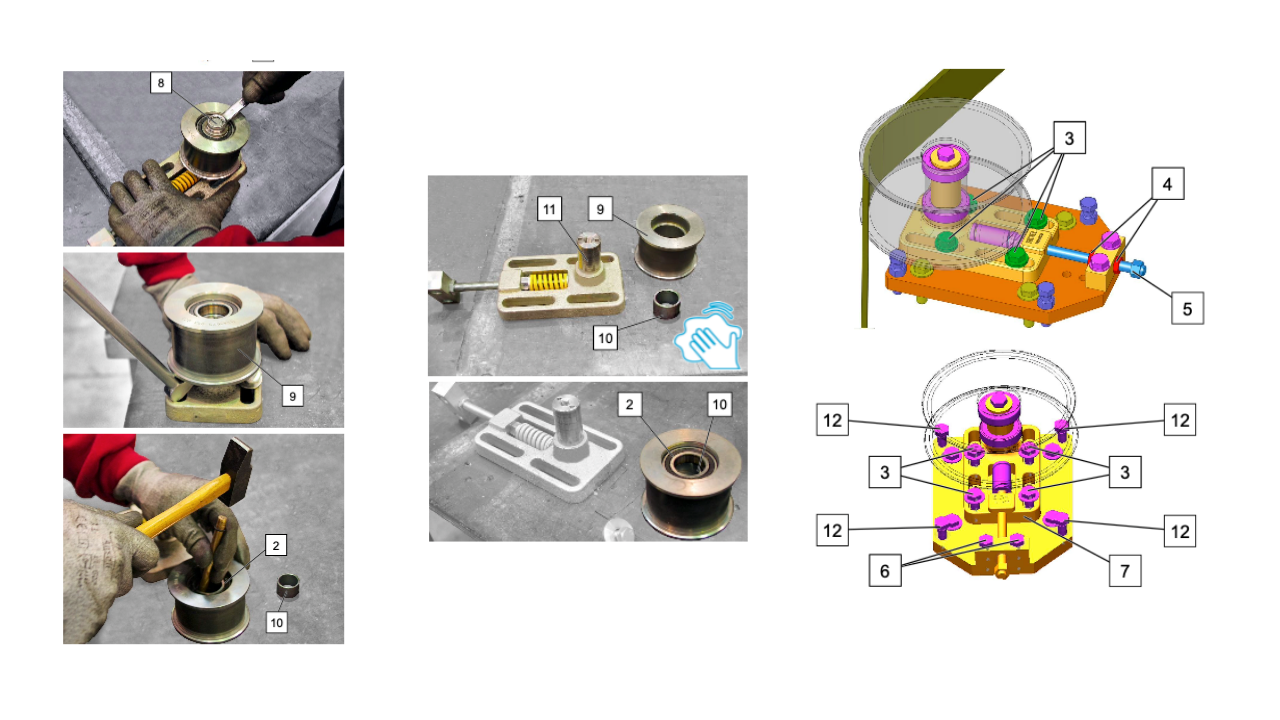

Disassembly

1. Loosen and remove the knurled brake nut (2).

2. Remove the following parts:

– Bearings(1),

– Separator (3).

Attaching the part

1. Replace the following parts:

– Locking cylinders (1),

– Notched locknut (2).

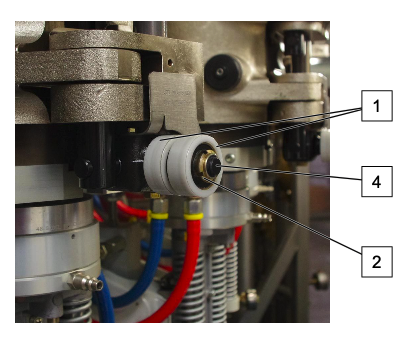

2. Clean the shaft (4) and spacer (3) with a clean, dry cloth.

3. Perform the subtraction in the reverse order, making sure that:

• Insert the spacer (3) between the 2 new rollers (1).

4. Check that the bearings (1) rotate correctly.

5. Repeat the operations at the fan stations.