As someone who is passionate about technology and manufacturing, I have always been fascinated by CNC machines. These machines have revolutionized the way we produce goods and have made manufacturing more efficient and cost-effective. In this article, I will delve into the world of CNC machines, exploring what they are, how they work, and why they are essential in modern manufacturing.

CNC Machines

CNC stands for Computer Numerical Control. In simple terms, a CNC machine is a machine that is controlled by a computer. The machine is programmed to follow specific instructions, which are entered into the computer. These instructions tell the machine what to do, where to move, and how fast to move.

CNC machines are used in a wide range of manufacturing applications, from aerospace to automotive to medical devices. They have replaced traditional manual machines, such as lathes and mills, and have made production faster, more precise, and more efficient.

What is CNC? Understanding the Basics

CNC machines are essentially robots that are designed to manufacture products. They can be programmed to perform a variety of tasks, from drilling and cutting to welding and engraving. The machines are controlled by software, which is designed to interpret the instructions and execute them.

One of the main advantages of CNC machines is that they are highly accurate and can produce parts with extremely tight tolerances. This level of precision is essential in many industries, such as aerospace and medical devices, where even the slightest deviation from the design can have serious consequences.

The Evolution of CNC Machines

CNC machines have come a long way since their inception in the 1950s. The first CNC machines were large and expensive, and they required highly skilled operators to program and run them. Over time, the machines became smaller, more affordable, and more user-friendly.

Today, CNC machines are used in a wide range of industries, and they are an essential part of modern manufacturing. They have become faster, more accurate, and more versatile, and they continue to evolve as technology advances.

Advantages of CNC Machines in Manufacturing

There are many advantages to using CNC machines in manufacturing. One of the most significant benefits is that they increase productivity and efficiency. CNC machines can work around the clock, and they require very little human intervention. This means that they can produce parts much faster than manual machines, and they can do so with greater accuracy.

Another advantage of CNC machines is that they can produce complex parts that would be difficult or impossible to produce with manual machines. This opens up new possibilities for designers and engineers, as they can create parts that were previously thought to be too complex or too expensive to produce.

Types of CNC Machines – Milling vs. Turning

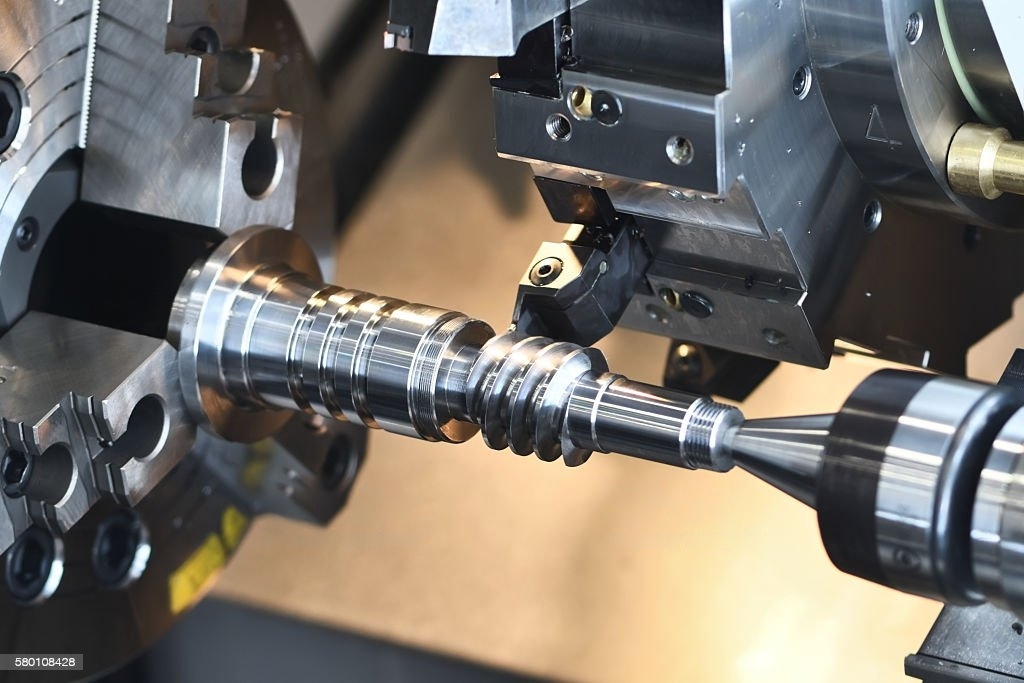

There are two main types of CNC machines: milling machines and turning machines. Milling machines are used to cut and shape materials, while turning machines are used to produce cylindrical parts.

Milling machines can be used to produce a wide range of parts, from simple brackets to complex engine components. They can be used to cut a variety of materials, including metal, plastic, and wood. Turning machines, on the other hand, are used to produce cylindrical parts, such as shafts, bolts, and screws.

CNC Milling Machines – How They Work

CNC milling machines are one of the most common types of CNC machines used in manufacturing. They work by using a rotating cutting tool to remove material from a workpiece. The cutting tool is controlled by a computer, which tells it where to move and how much material to remove.

The workpiece is held in place by a vice or other fixture, and the milling machine moves the cutting tool around the workpiece, removing material until the desired shape is achieved. CNC milling machines are highly accurate and can produce complex parts with tight tolerances.

CNC Manufacturing: The Future of Production

CNC manufacturing is the future of production. As technology continues to advance, we can expect to see even more advanced and versatile CNC machines that can produce parts faster, more accurately, and more efficiently than ever before.

CNC machines are already being used in a wide range of industries, from aerospace to automotive to medical devices. As the technology becomes more widespread and more affordable, we can expect to see even more applications for CNC machines in the future.

Applications of CNC Machines in Different Industries

CNC machines are used in a wide range of industries, and their applications are almost limitless. In aerospace, CNC machines are used to produce complex parts for aircraft engines and components. In automotive manufacturing, CNC machines are used to produce parts for engines, transmissions, and drivetrains. In the medical device industry, CNC machines are used to produce implantable devices and surgical instruments.

CNC machines are also used in the production of consumer goods, such as electronics, appliances, and furniture. They are used to produce everything from smartphone components to kitchen cabinets.

CNC Machine Maintenance and Safety

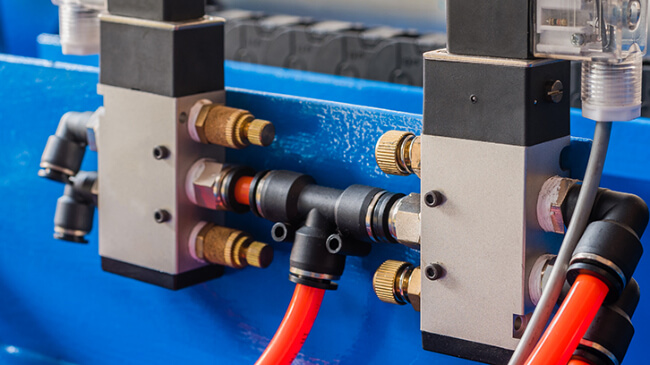

Like any piece of machinery, CNC machines require regular maintenance to ensure that they are operating at peak efficiency. Regular maintenance can help to prevent breakdowns and extend the lifespan of the machine. Operators should also be trained in the proper use of the machine and should follow all safety guidelines to ensure that accidents are avoided.

Investing in a CNC Machine – Things to Consider

Investing in a CNC machine is a significant investment, and there are several things to consider before making a purchase. First, you should consider the specific needs of your business and the types of parts you will need to produce. You should also consider the space requirements, as CNC machines can be quite large.

You should also consider the level of training and support that you will need to operate the machine. Finally, you should consider the cost of the machine, as well as any ongoing maintenance and repair costs.

Conclusion

CNC machines have revolutionized the way we manufacture goods, and they have made production faster, more efficient, and more accurate. They are used in a wide range of industries, from aerospace to automotive to medical devices, and their applications are almost limitless.

Investing in a CNC machine is a significant investment, but it can pay off in increased productivity, efficiency, and accuracy. If you are considering purchasing a CNC machine, be sure to do your research and consider all of the factors involved. With the right machine and the right training, you can take your manufacturing to the next level.