In the realm of industrial processes, maintaining cleanliness and hygiene is of utmost importance. A vital aspect of this is ensuring that equipment, pipelines, and tanks are thoroughly cleaned to prevent cross-contamination and maintain product quality. However, achieving efficient and effective cleaning can be challenging without the right approach. This is where the Cleaning in Place (CIP) process comes into play. In this blog post, we will delve into the details of the CIP process, its significance, and the steps involved in its implementation.

What is CIP?

Cleaning in Place (CIP) is a method used in various industries, such as food and beverage, pharmaceuticals, and dairy, to clean and sanitize equipment and processing systems without the need for disassembly. It is a closed-loop automated system that saves time, labor, and resources compared to manual cleaning methods.

The Significance of CIP

Efficiency: The CIP process allows for efficient and effective cleaning by eliminating the need for disassembly and manual cleaning. It saves time and minimizes production downtime, resulting in increased productivity and reduced costs.

Consistency: CIP systems ensure consistent and repeatable cleaning procedures. The process can be precisely controlled, ensuring the same cleaning parameters are met every time. This consistency is crucial for maintaining product quality and meeting regulatory requirements.

Safety: CIP systems minimize human contact with hazardous chemicals, hot surfaces, and confined spaces. By automating the cleaning process, they reduce the risk of injuries and exposure to potentially harmful substances, enhancing worker safety.

Steps Involved in the CIP Process

- Pre-rinse: The first step is to remove any loose debris or product residue from the equipment by flushing it with water or an appropriate cleaning solution. This step prepares the equipment for the main cleaning process.

- Cleaning Solution Preparation: A cleaning solution is prepared by mixing water with specific detergents or sanitisers based on the equipment and soil type. The solution is then circulated through the system, ensuring all surfaces come into contact with the cleaning agents.

- Circulation and Soak: The cleaning solution is circulated through the equipment, pipelines, and tanks, dislodging and dissolving any remaining soil or deposits. Depending on the level of cleaning required, the solution may be recirculated or left to soak for a specific duration.

- Post-rinse: After the cleaning solution has done its job, a thorough rinse with water follows to remove any residual cleaning agents. This step is essential to prevent contamination of subsequent product batches and to ensure the equipment is ready for the next production cycle.

- Final Sanitization: In certain industries, a sanitization step is necessary to eliminate any remaining microorganisms. This involves circulating a sanitizing solution through the system to kill bacteria, viruses, and other harmful pathogens.

CIP Equipment

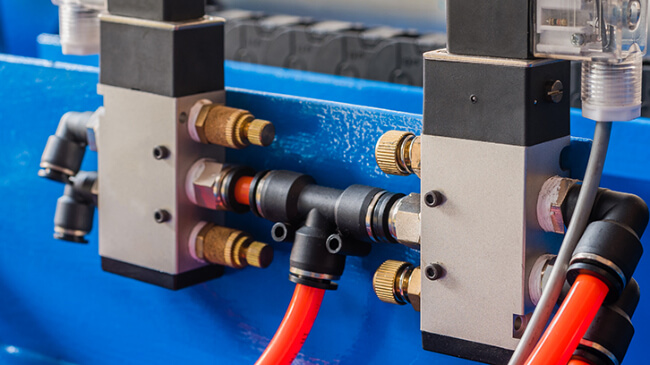

CIP systems comprise various components, including cleaning solution storage tanks, pumps, valves, sensors, and heat exchangers. These components work together to ensure an efficient and controlled cleaning process. Advanced CIP systems may incorporate automation and monitoring technologies for enhanced precision and traceability.

CIP Validation and Documentation

To comply with industry regulations and quality standards, CIP processes require validation and documentation. This involves verifying the effectiveness of the cleaning process and ensuring that critical parameters such as temperature, time, and chemical concentration are met. Detailed records are maintained to provide evidence of compliance and to aid in troubleshooting or process improvements.

The Cleaning in Place (CIP) process is a crucial aspect of maintaining cleanliness, hygiene, and product quality in industrial settings. By automating and streamlining the cleaning process, CIP systems offer significant advantages. They enhance efficiency, ensure consistency, and improve safety while complying with industry